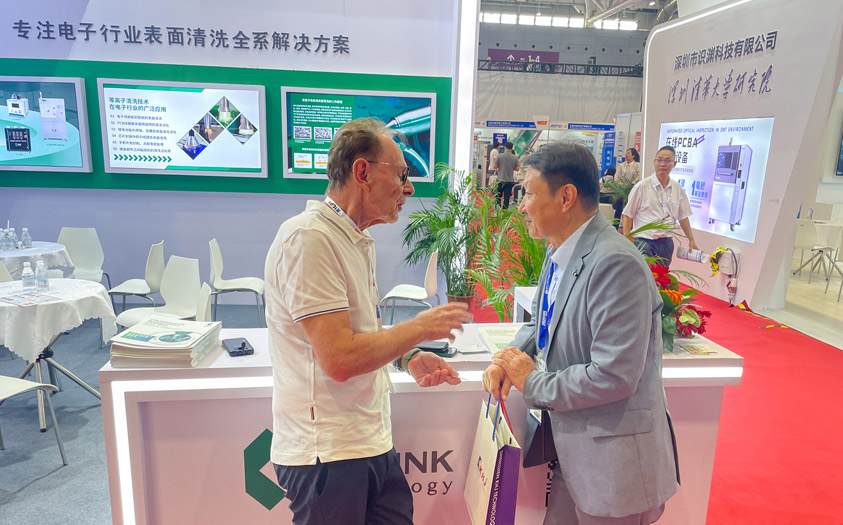

From October 11 to 13, 2023, NEPCON ASIA 2023 Asian Electronic Manufacturing Exhibition will be held as scheduled at the Shenzhen International Convention and Exhibition Center (Baoan New Hall). As the focusing surface adhesionl solution service and basic component testing of the electronics industry chain As an important domestic brand in the application field, Keylink Technology made a stunning appearance at this exhibition with its efficient plasma processing equipment, attracting many Chinese and foreign get interest to stop and communicate.

The special plasma surface treatment system PL-5050P-S with smart interface, Power-real-time display, alarm query, frequency display, 485 communication, and can communicate with the host computer to collect data and power. Continuously adjustable and other advantageous features are suitable for surface cleaning and activation of circuit boards, IC chips, lithium batteries, mobile phone casings and other materials. This also provides relevant solutions for the continuously developing process applications in the electronics industry, with its high efficiency and accuracy. Helps improve product quality.