Table of Contents

TogglePlasma cleaning is an advanced method used across many industries. Its primary purpose is to clean and modify surfaces for better performance. It uses a plasma surface treatment machine that ionizes gases to create reactive plasma.

As more industries adopt this technology, plasma cleaning equipment’s importance grows. This is especially true in fields where surface cleanliness and bonding quality are crucial.

What is Plasma Cleaning?

Plasma cleaning is a method for cleaning and modifying surfaces. It uses a plasma surface treatment machine that ionizes gas to create plasma.

Plasma cleaning improves adhesion. Additionally, it ensures surfaces are clean without harsh chemicals. This innovative cleaning treatment is eco-friendly. This is because plasma cleaning reduces environmental impact.

Plasma surface treatment is vital in industries that require ultra-clean surfaces. It effectively removes organic contamination while enhancing surface energy. Due to such an effect, the treatment ensures better bonding between substrates and adhesives.

Plasma cleaning solutions are typically used before coating or printing. This step is necessary to improve adhesion on materials like metals, plastics, and glass.

vaccoat.com, Plasma Cleaning | What is Plasma Cleaner?, 2024

Key Components of Plasma Cleaner Equipment

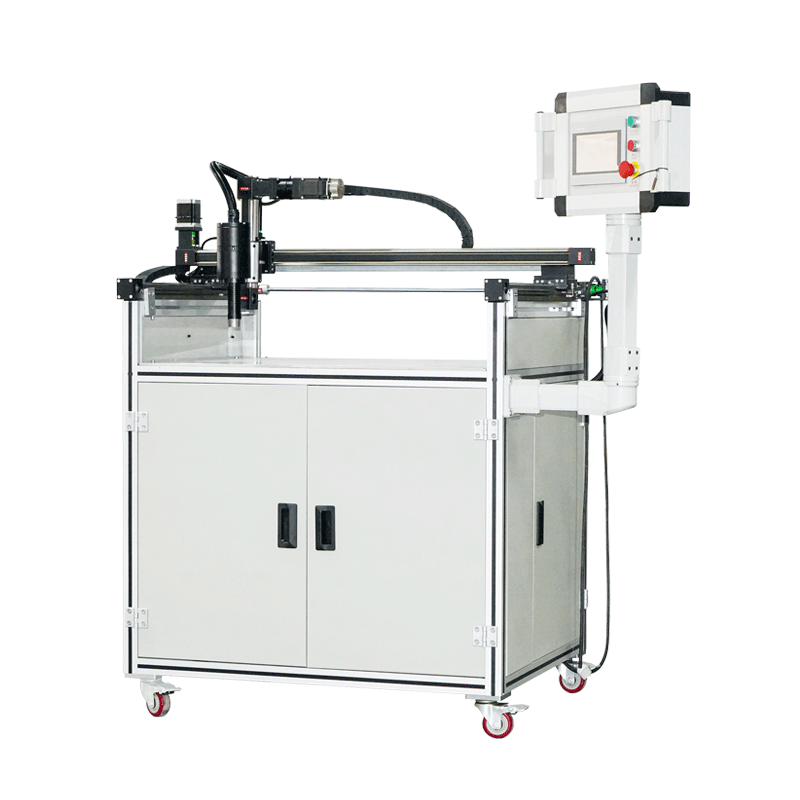

A plasma surface treatment machine has several key parts:

- Vacuum Chamber or Open-Air Chamber: This is used depending on whether it is a low-pressure or atmospheric system.

- Power Supply: This provides the energy needed to generate plasma. It ionizes the gas to create the reactive plasma for cleaning.

- Gas Feed System: This supplies gases such as oxygen, argon, or nitrogen that create plasma. The type of gas used can affect the cleaning outcome.

- Control Panel: This part allows for precise control over the plasma cleaning process. This ensures consistent results across cleaning cycles.

Applications of Plasma Cleaning in Various Industries

Packaging

In the packaging industry, plasma surface treatment is essential. It cleans and activates surfaces of plastic, metal, or paper packaging materials.

Printing

In the printing industry, plasma surface treatment improves ink adhesion. This ensures that inks bond properly to non-porous surfaces. Thus, businesses can produce better print quality.

Wires and Cables

The plasma cleaning process is used in the wires and cables industry. It cleans and activates surfaces before applying insulation or coatings. Plasma treatment removes residues that can compromise adhesion.

Consumer Goods

In the consumer goods industry, plasma surface treatment improves adhesion between materials. It is especially useful for materials that resist bonding.

Electronic

The electronics industry relies on plasma cleaning for high-performance devices. Before applying sensitive components, a clean surface is a must. Plasma treatment effectively removes contaminants at the molecular level. By so doing, it improves reliability and performance.

Automotive

In the automotive industry, plasma surface treatment prepares surfaces for bonding and painting. This ensures that coatings remain intact, even under harsh conditions.

Medical

The medical industry benefits from plasma cleaning, too. It is helpful in sterilizing devices and instruments. Plasma treatment even ensures surfaces are contaminant-free. Plasma coating technologies may also enhance biocompatibility for implants and tools.

Conclusion

Plasma cleaning technology is a versatile solution for ensuring ultra-clean surfaces. The applications span several industries. These would include packaging and printing to electronics, automotive, and medical devices.

Keylink Technology is a leader in providing customized plasma systems. Our solutions are designed to meet the specific needs of various industries. We deliver over 2,000 pre-treatment solutions annually. This suggests how in-demand our products are to several businesses around the globe.

References

- Science Direct – Plasma Cleaning – An Overview; Creator – Andrea Longobardo, 2021 (https://www.sciencedirect.com/topics/physics-and-astronomy/plasma-cleaning)

- Plasma medicine research highlights antibacterial effects and potential uses; Penn State University; 2020 (https://www.psu.edu/news/research/story/plasma-medicine-research-highlights-antibacterial-effects-and-potential-uses)